Coal and Ash Handling Equipment

Ash Pump Volute Casings

BMW Steels Ltd. has specialization in manufacturing, exporting and supplying Ash Pump Volute Casings that are categorized into parts of Coal Ash Handling Equipments. We offer lined Ash Pump Volute Casings to client which is helpful in reducing the severe erosion of the product, thereby reducing the overall maintenance cost.

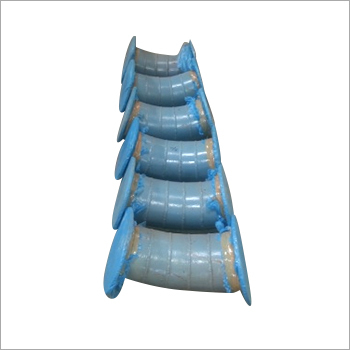

Bends and Y-Piece

We are manufacturing Bends and Y-Piece that are critical part of Coal Ash Handling Equipments. Considering the importance of precision dimensioned Bends and Y-Piece, it becomes pivotal to determine their wear rate. For this, three factors play a major role - 1) conveying velocity of ash, 2) density of the ash and 3) size of ash particles. To reduce the wear rate of these ash handling equipment parts, alumina ceramic is used in the systems. For the benefit of clients, we also offer wear resistant Ni-Hard castings that have the purpose of analyzing the wear possibility. In this regard, the expertise of BMW Steels Ltd. resides in filling the linings in casings developed at our works.

Application areas

Application areas

- Aluminum plants

- Cement plants

- Coal and mineral washeries

- Coal fired thermal power projects

- Mineral processing units

- Steel plants

Coal Bunkers and Chutes

BMW Steels Ltd. has specialization in manufacturing, exporting and supplying ceramic lined coal bunkers and chutes. These products are some of our most popular parts of Coal Ash Handling Equipments. The lining done on the coal bunkers allows increased flow of the coal, which it is passed through the bunkers and chutes. It allows unbelievable resistance against wear and tear apart from having highest impact strength. These parts of ash handling equipment also have surpassing resistance against abrasion and corrosion.

Its specific features are:

Its specific features are:

- Low coefficient of friction

- No moisture abortion

- Resistance against abrasion, chemical and corrosion

- Weldable liners are available